Picture this: You’re rushing to get your laundry done before an important meeting, and suddenly your washing machine displays the dreaded “E1” error code. Your clothes are soaking wet, the cycle has stopped, and you’re left wondering what went wrong. This frustrating scenario affects thousands of households daily, turning a simple chore into a major headache.

The consequences of ignoring this error can be costly – from damaged clothes and potential water damage to expensive repair bills. But here’s the good news: most E1 errors can be resolved quickly with the right knowledge and approach.

This comprehensive guide will walk you through everything you need to know about fixing E1 errors across all major washing machine brands, saving you time, money, and unnecessary stress.

The E1 error code is one of the most common washing machine error codes, but its meaning can vary depending on your machine’s brand and model. Understanding what this error signifies is the first step toward resolving it effectively.

| Brand | E1 Error Meaning | Primary Cause |

|---|---|---|

| Whirlpool | Water supply issue | Slow water filling |

| Samsung | Water supply error | Insufficient water pressure |

| LG | Water level sensor problem | Sensor malfunction |

| TCL | Slow water filling | Water supply blockage |

| Midea | Water inlet error | Clogged inlet valve |

| Sharp | Water supply fault | Tap/valve issues |

| Toshiba | Water filling problem | Hose blockage |

Key Insight: While E1 generally relates to water supply issues, the specific cause varies by manufacturer. This is why a one-size-fits-all approach often fails.

Before diving into solutions, let’s identify the root causes behind this error. Understanding these will help you diagnose the problem more accurately.

Pro Tip: Start with the simplest solutions first – many E1 errors are resolved by basic troubleshooting steps that take less than 5 minutes.

Follow these systematic troubleshooting steps to resolve your washing machine’s E1 error. Each step builds upon the previous one, starting with the most common and easily fixable causes.

Time Required: 2-3 minutes

Success Indicator: If water flows freely from nearby taps and no leaks are visible, proceed to Step 2.

Time Required: 5-7 minutes

Important Safety Note: Always turn off water supply before disconnecting hoses to prevent flooding.

Time Required: 10-15 minutes

Most washing machines have additional filters that can become clogged over time:

Time Required: 5-8 minutes

If water supply issues aren’t the culprit, the problem might be with your machine’s sensors:

Diagnostic Clue: If E1 appears immediately, it’s likely a sensor issue. If it appears after several minutes of attempted filling, it’s probably a water supply problem.

Time Required: 3-5 minutes

Sometimes, a simple reset can clear temporary electronic glitches:

Success Rate: This method resolves approximately 20% of E1 errors, particularly those caused by temporary electronic hiccups.

Different manufacturers implement unique systems, requiring tailored approaches for optimal results.

Specific Issue: E1 typically indicates the washer is taking too long to fill with water.

Whirlpool-Specific Steps:

Model-Specific Note: Whirlpool Cabrio models may require a different reset sequence – hold the “Start” button for 3 seconds while the lid is closed.

Specific Issue: E1 indicates insufficient water supply or pressure.

Samsung-Specific Steps:

Pro Tip: Samsung machines are particularly sensitive to water pressure fluctuations. If your home has variable pressure, consider installing a pressure regulator.

Specific Issue: E1 often relates to the water level sensor rather than actual water supply.

LG-Specific Steps:

Technical Note: LG machines use advanced load sensing technology that can be disrupted by uneven loads or sensor contamination.

Specific Issue: E1 typically means water is filling too slowly.

TCL/Midea-Specific Steps:

When basic steps don’t resolve the issue, these advanced techniques can help identify deeper problems.

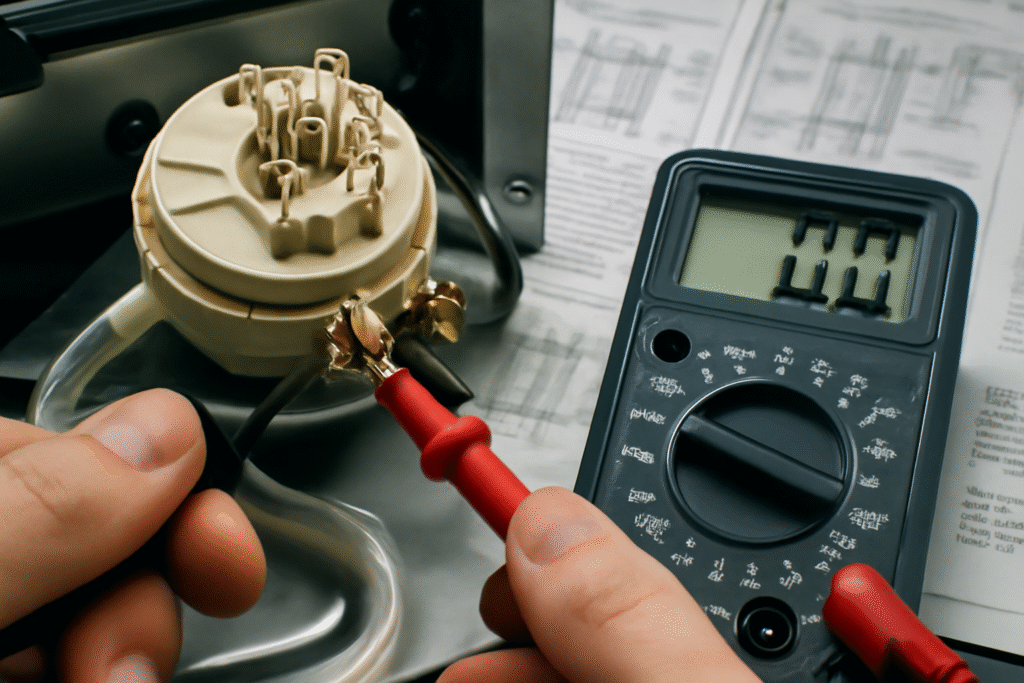

Warning: Only attempt if you’re comfortable with basic electrical work, or call a professional.

Use a water pressure gauge (available at hardware stores) to measure:

If pressure is consistently below 20 PSI, contact a plumber to address your home’s water pressure issues.

Proactive maintenance is always more cost-effective than reactive repairs. Follow these tips to minimize E1 error occurrences:

Money-Saving Tip: Regular maintenance costs approximately $30-50 annually but can prevent repair bills ranging from $150-400.

While many E1 errors can be resolved through DIY troubleshooting, certain situations require professional expertise:

Cost Expectations:

No, continuing to use the machine with an E1 error can cause additional damage to internal components. Address the error before using the machine again.

Try basic troubleshooting steps first. If the error persists after following this guide’s steps, contact a professional within 24-48 hours to prevent potential water damage.

Yes, hard water causes mineral buildup in screens and valves, leading to more frequent E1 errors. Consider installing a water softener system if you have consistently hard water.

Occasional resets are safe, but frequent resets indicate an underlying problem that needs professional attention.

Yes, extremely cold weather can cause pipes to freeze, leading to E1 errors. Hot weather can affect water pressure in some municipal systems.

Install a water pressure gauge on an outdoor spigot. Readings below 20 PSI will likely cause E1 errors in most washing machines.

The E1 error in washing machines, while frustrating, is typically a solvable problem that doesn’t require expensive professional repairs. By following this comprehensive guide, you now have the knowledge and tools to:

Remember: Start with the simplest solutions first – checking water supply and cleaning inlet screens resolves over 70% of E1 errors. If these steps don’t work, progress through the more advanced troubleshooting techniques.

Your next step: Begin with Step 1 of our troubleshooting guide right now. Most E1 errors can be resolved within 15-30 minutes, getting your laundry routine back on track quickly.

Have you successfully fixed your E1 error using this guide? Share your experience in the comments below to help other readers facing similar issues.

This guide is regularly updated to include the latest troubleshooting techniques and brand-specific solutions. Bookmark this page for future reference and share it with others who might benefit from this comprehensive E1 error solution guide.